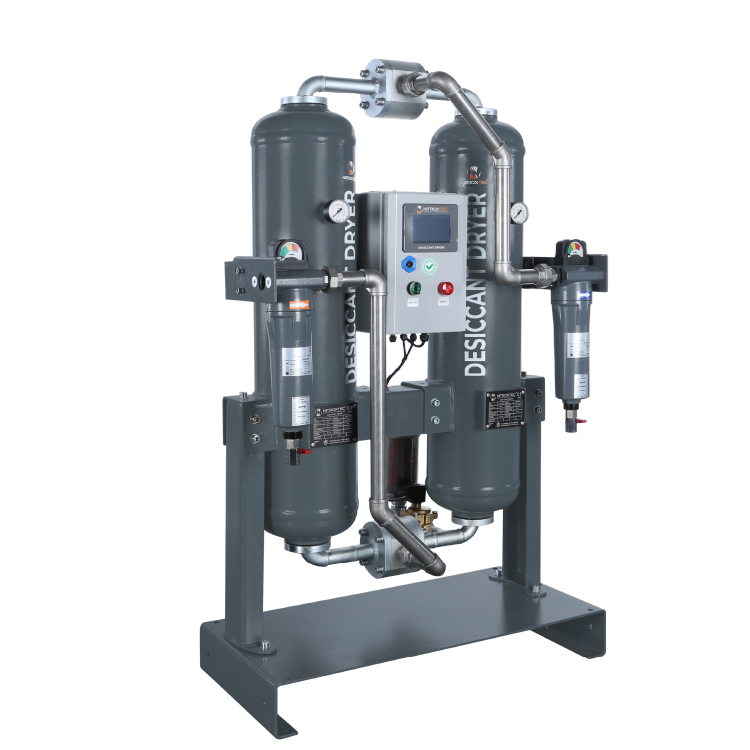

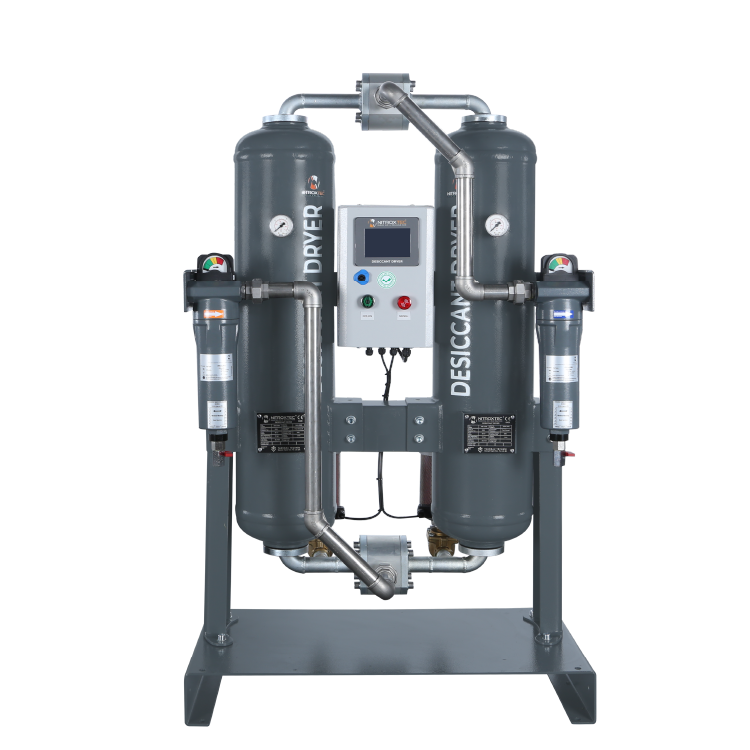

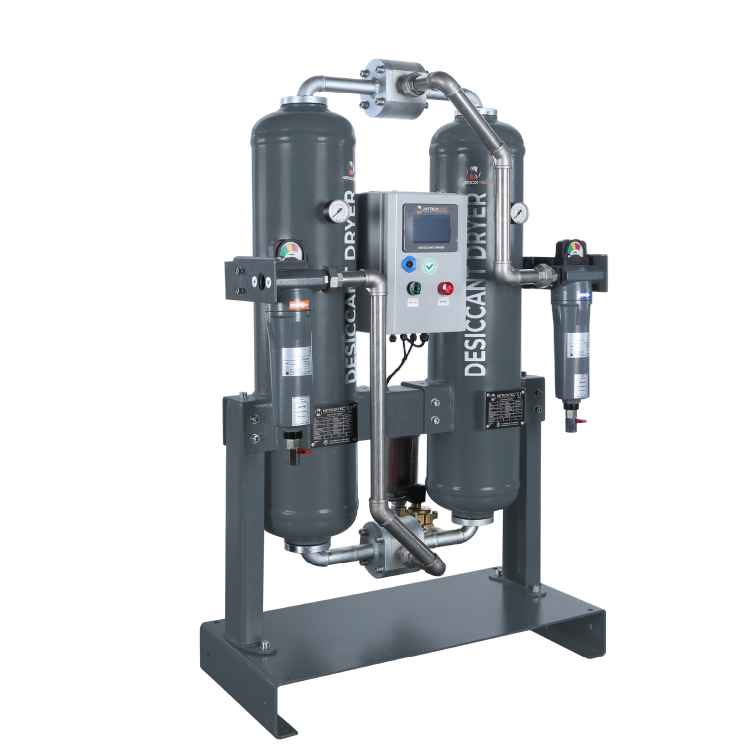

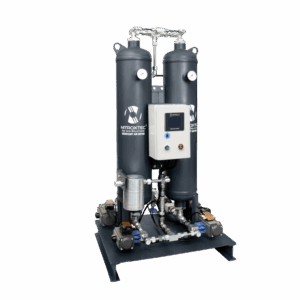

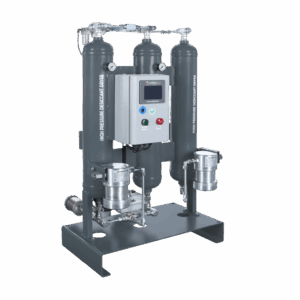

Nitroxtec Desiccant Dryers (Heatless Type)

Clean Air, Reliable Drying — Without External Energy

Nitroxtec Heatless Desiccant Dryers are engineered to provide clean, ultra-dry compressed air for industries where moisture poses a risk to product quality, equipment longevity, or safety. With dew points down to –40 °C or –70 °C, these dryers meet stringent air purity standards and operate without the need for external heating—offering a reliable, low-maintenance, and energy-efficient solution.

What is a Desiccant?

A desiccant is a hygroscopic material that absorbs moisture from the air. In desiccant air dryers, moist compressed air is passed over high-performance materials such as silica gel, molecular sieve, or activated alumina, which trap the water vapor. As the desiccant becomes saturated, it must be regenerated to restore its drying capacity.

To ensure continuous operation, desiccant dryers are typically built with two towers:

-

One tower dries the compressed air

-

The other regenerates the saturated desiccant using a small portion of already dried air (purge air)

The towers switch automatically based on a timed cycle, ensuring uninterrupted drying.

Key Features

| Feature | Benefit |

|---|---|

| Dew Point Options: –40 °C or –70 °C | Tailored for specific moisture control needs in critical applications |

| Dual-Tower Adsorption Design | Continuous operation with automatic tower switching for drying and regeneration |

| No External Heat Required | Heatless design minimizes energy usage and simplifies operation |

| Low Purge Air Loss | Optimized regeneration process reduces air waste |

| High-Quality Desiccant Media | Uses activated alumina, silica gel, or molecular sieve for long-lasting performance |

| Wide Capacity Range (18–10.800 m³/h) | Suitable for small to large-scale industrial compressed air systems |

| Electronic Control Panel with Display | Real-time monitoring with alarms and user-friendly interface |

| Optional Dew Point Sensor | Smart operation and energy savings |

| European Valves & Silencers | Quiet, durable, and long-lasting components |

| Built-in Filtration & Drainage | Protects desiccant media and ensures clean outlet air |

Working Principle

Moist compressed air is directed into one of the two towers filled with desiccant. The desiccant adsorbs water vapor, producing ultra-dry air. A small portion of this dried air (purge air) is then used to regenerate the saturated desiccant in the second tower by removing accumulated moisture. The system automatically alternates the towers to provide uninterrupted operation—all without any external heat source.

This adsorption drying process ensures consistent dew point performance with low energy consumption and simple maintenance.

Why Choose Nitroxtec Heatless Desiccant Dryers?

-

Desiccant Adsorption Technology – Proven moisture removal using silica gel, alumina, or molecular sieve

-

No Heating Elements – Operates completely without external heaters or electrical heating systems

-

Configurable Dew Points – Choose between –40 °C and –70 °C based on your application

-

Low Maintenance – Minimal moving parts and reliable automatic regeneration

-

ISO 8573-1:2010 Class 2 Compliance – Clean, dry air for critical industries

-

Scalable Solutions – Wide range of flow rates and options for all sectors

Applications

-

Laser Cutting Systems (Fiber Laser, 16–20 Bar)

Prevents oxidation, nozzle clogging, and moisture-related defects -

Pharmaceutical Industry

Delivers ultra-dry air for moisture-sensitive packaging and cleanrooms -

Food & Beverage Production

Maintains hygiene and prevents spoilage in packaging and bottling lines -

Electronics & Semiconductors

Protects static-sensitive components in SMT lines and PCB manufacturing -

Precision Manufacturing & CNC Systems

Prevents rust and sticking in pneumatic tools, actuators, and robotics -

Automotive & Paint Finishing

Supports consistent coating quality and air-powered tool operation -

General Industrial Air Systems

Suitable for any application where clean, dry compressed air is essential

Reliable Moisture Control. Zero Heat. Maximum Efficiency.

Nitroxtec Heatless Desiccant Dryers combine reliable adsorption drying technology with smart automation and efficient performance. Designed for environments where dryness and reliability are non-negotiable, these dryers ensure your operations stay clean, safe, and energy-efficient—day in, day out.