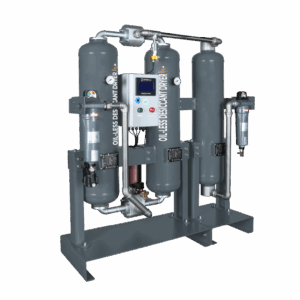

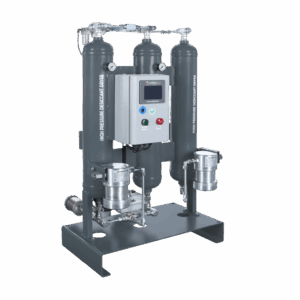

Nitroxtec High Pressure Desiccant Dryers (Heatless Type)

Ultra-Dry, Clean Air — Now Up to 300 Bar

Nitroxtec High Pressure Desiccant Dryers are specifically designed to deliver moisture-free compressed air at pressures ranging from 40 to 300 bar. Built on reliable adsorption drying principles, these systems use high-performance desiccants such as activated alumina, silica gel, or molecular sieve to achieve dew points as low as –40 °C or –70 °C—all without external heating.

Whether you’re supporting high-pressure laser cutting, PET bottling, or critical gas processes, Nitroxtec ensures uninterrupted drying with maximum reliability and minimal energy consumption.

What is a Desiccant?

A desiccant is a hygroscopic material that absorbs moisture from the air. In desiccant dryers, wet compressed air flows over materials like silica gel, molecular sieve, or activated alumina, which remove water vapor. As the desiccant becomes saturated, it must be regenerated to regain its drying capacity.

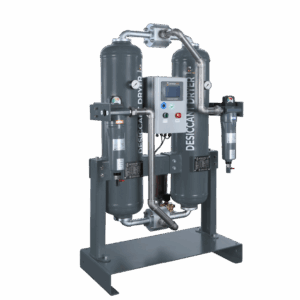

To enable continuous operation, the dryer system uses two towers:

-

One tower dries the incoming air

-

The other regenerates with a small amount of purge air from the dried outlet stream

Towers switch roles automatically based on a timed cycle—delivering reliable, high-pressure drying without interruption.

Key Features

| Feature | Benefit |

|---|---|

| High Pressure: 40–300 bar | Engineered for high-pressure industrial and specialty applications |

| Dew Point Options: –40 °C or –70 °C | Adjustable to meet your process moisture requirements |

| Dual-Tower Adsorption Design | Continuous drying with automatic regeneration |

| No External Heat Required | Heatless operation for lower energy consumption |

| Low Purge Air Loss (typically 10–15%) | Optimized regeneration to minimize air and energy waste |

| High-Performance Desiccant Media | Long service life and superior drying performance |

| Electronic Control Panel | Live monitoring, alarms, and automated control |

| Optional Dew Point Sensor | Smart mode control for energy efficiency |

| European-Quality Valves & Silencers | Quiet, reliable operation under high-pressure conditions |

| Robust High-Pressure Filtration System | Protects desiccant and downstream equipment at elevated pressures |

Working Principle

Moist air at high pressure is directed into one of two desiccant-filled towers, where it passes through adsorbent media and is dried to the required dew point. A small portion of the dried, high-pressure air is used to regenerate the desiccant in the alternate tower. Towers switch cyclically and automatically to provide continuous drying, with no external heat or electrical heaters needed.

Why Choose Nitroxtec High Pressure Desiccant Dryers?

-

Designed for 40–300 Bar Systems – Built for laser cutting, PET, and other high-pressure uses

-

Desiccant-Based Adsorption Drying – Efficient and proven moisture removal

-

Zero Heating Required – Low operational cost and no heating elements

-

Customizable Dew Point – Choose –40 °C or –70 °C based on your process

-

Low Maintenance – Durable components, long desiccant life, easy service

-

ISO 8573-1:2010 Class 2 Compliant – Meets stringent air quality requirements

Applications

-

High-Pressure Laser Cutting Systems (16–40 bar+)

Prevents oxidation, nozzle clogging, and moisture-related cutting defects -

PET Blow Molding & Bottling Plants

Ensures moisture-free air for bottle forming and packaging -

Industrial Gas Filling & Cylinder Applications

Maintains gas purity and prevents internal corrosion -

Offshore & Marine Operations

Reliable high-pressure air for harsh and moisture-prone environments -

Defense & Aerospace Systems

Ultra-dry air for pneumatic launchers, breathing air systems, or fuel handling -

General High-Pressure Air Systems

Suitable for any process requiring clean, dry compressed air at elevated pressures

Maximum Pressure. Maximum Purity. Maximum Peace of Mind.

With Nitroxtec High Pressure Desiccant Dryers, you get a system built for extreme performance. Whether your needs are in high-pressure manufacturing, gas storage, or critical operations, Nitroxtec delivers clean, dry, and dependable air—every time.